This winter has been exceptionally long and cold, but we are lucky that spring is here.However, masks have become one of the most common items in plastic waste due to the COVID-19 pandemic, and a large number of disposable masks can even cause serious plastic pollution.

On the other side of the mountain, on the other side of the sea, there was a pile of discarded blue masks.Remember that the French Marine Conservation Organization once joked that "France has just ordered 2 billion face masks, and there will soon be more face masks in the Mediterranean than jellyfish", but this is only the beginning of the ecological damage caused by face masks.

According to some estimates, 129 billion face masks and 65 billion plastic bags are used around the world every month.Masks are the protector of human health, but also the death of many natural creatures.

Some masks will be properly disposed of, such as medical waste disposal stations and garbage recycling plants, but there are still a considerable proportion of masks that are not properly recycled by people. They are thrown about on roads, thrown into rivers, garbage not sorted, etc., all of which can be attributed to the ocean of giant human garbage cans due to improper disposal.

According to a report by OCEANS ASIA in December 2020, at least 1.56 billion masks are discarded worldwide!The masks are equivalent to 4,680 to 6,240 tons of plastic waste that ends up in the ocean or is buried in the ground, while the waste masks can take 450 years to degrade in the natural environment."Marine pollution kills 100,000 Marine mammals and sea turtles every year, a million seabirds, and many more fish, invertebrates and other animals."

Masks release microplastics and nano-plastics in water, as well as silicon nanoparticles and heavy metals such as lead, cadmium and copper, which can disrupt entire Marine life chains and contaminate drinking water.Marine plastic pollution is a worldwide problem, and if we at the top of the biological chain do not do something about it, we will suffer the consequences.

In addition to Marine life, monkeys in the wild in Malaysia are "studying" masks found on the roadside, or decomposing masks to use as food stuck in their throats, or accidentally put around their necks and strangled to death.Seagulls that are supposed to fly in the air wrap masks around their feet, which cannot be undone by their inflexible feet. As they are restricted to forage, they are either waiting for rescue or dying.

Masks are temporarily the god of protection for human beings, but they are the death of many natural creatures. Environmental protection is a worldwide problem, and no one can be immune from it. As the plastic industry, we should strive to move forward!

Fine-Blendhas been committed to keeping up with the trend of environmental protection, caring about environmental protection and understanding the needs of customers. At the same time, as a company with a sense of temperature and social responsibility, we have already met Bio-Master® biodegradable plastic additives and Eco-Batch® high-performance recycled plastic additives.

In this issue, we meet Eco-Batch® series of renewable and traceable PP graft compatibilizer: ECO-121.

First of all, weneed to introduce GRS certification. The application for GRS certification must meet the requirements of traceability, environmental protection, social responsibility, regeneration mark and general principles.The global recycling standard applies to any product containing at least 20% recycled material.Each production stage must be certified, starting with the recovery stage, and ultimately ends with the final seller in a business-to-business transaction.

Eco-121 developed by Fine-BlendR&D team has renewable traceability, with the same amount of addition, with the same performance, with the same amount of substitution, to ensure that our customers on the premise of quality assurance, the introduction of renewable traceable raw materials for environmental protection, renewable and recyclable contribution to the social force.

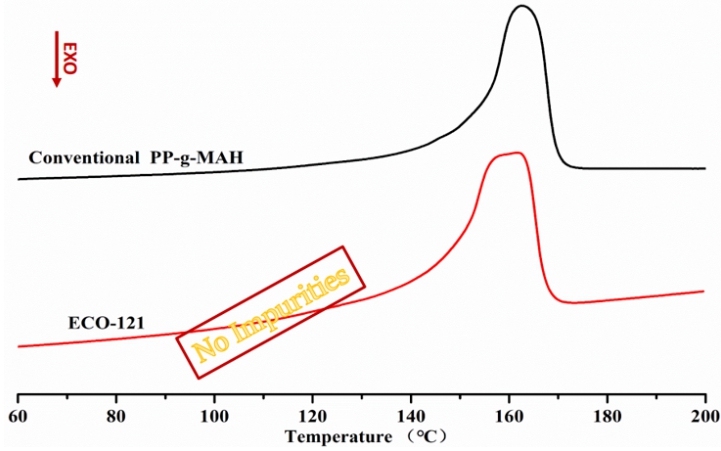

FIG. 1 Comparisonof DSC curves of ECO-121 and original PP-MAH

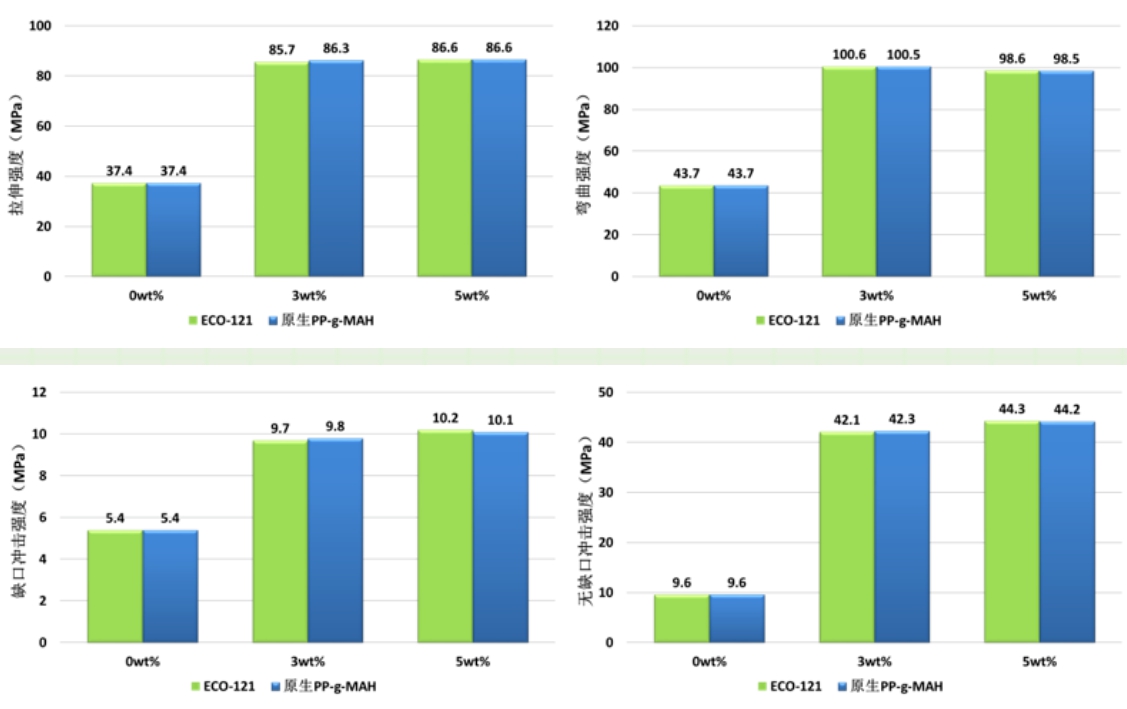

FIG. 2 Mechanical properties of ECO-121 and native PP-MAH in PP/GF30

The above chart shows that the mechanical properties of ECO-121 and the original PP-G-MAH in the PP/GF30 system are basically the same, so the downstream customers can be assured to purchase the renewable PP-based Eco-121 compatibilizer without affecting the mechanical properties in the material system.

To sum up, ECO-121 is suitable for PP-g-MAH compatibilizer applications and meets GRS certification, which can be used with any recycled input material and can be applied to any supply chain. This discovery is bound to achieve a certain sense of environmental recycling.

Previous: New Trademarks for Fine-Blend Next: Biodegradable Plastics Market and Application of HPC-3510P