Case 1: CMG5805-L improved low temperature toughness of PA6 and PA66

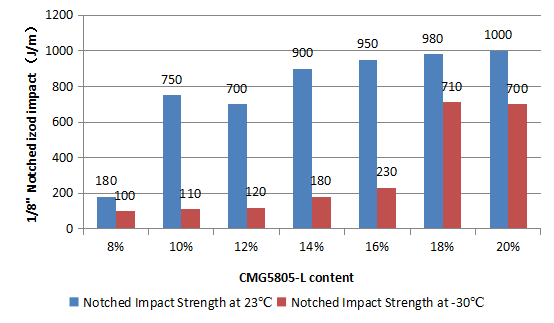

Fig.1 The effect of CMG5805-L on impact strength of toughening PA6

In toughening PA6, adding 10% of CMG5805-L, notched impact strength at 23℃ reach the brittle-ductile transition, and adding 18% of CMG5805-L, notched impact strength at -30℃ reach the brittle-ductile transition (Fig.1). (PA6 viscosity of 2.45 in experiment)

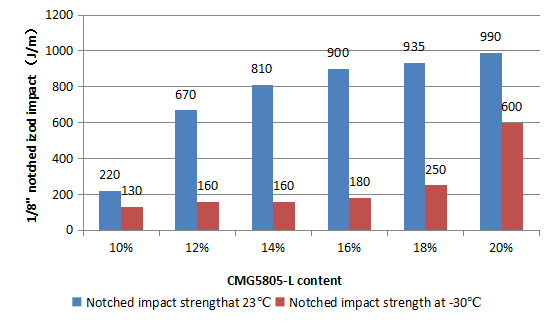

Fig.2 The effect of CMG5805-L on impact strength of toughening PA66

In toughening PA66, adding 12% of CMG5805-L, the notched impact strength at 23℃ reach the brittle-ductile transition, and adding 20% of CMG5805-L, notched impact strength at -30℃ reach the brittle-ductile transition (Fig.2). (PA66 viscosity of 2.7 in experiment)

Case 2: The influence of CMG5805-L on aging properties (aging temperature: 150℃) of toughening PA6

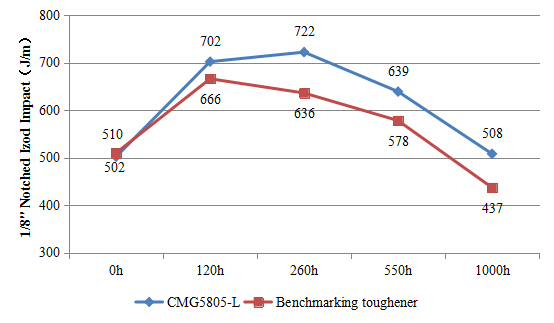

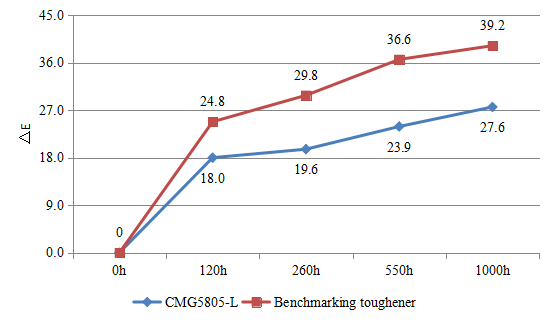

Fig.3 The notched impact variable data of toughening PA6 along with aging time

As shown in Fig.3, parallel adding CMG5805-L with adding US benchmarking toughener in toughening PA6, with the increasing of the aging time, the notched impact strength were increased before they were reduced, however, adding CMG5805-L is better in toughness retention.

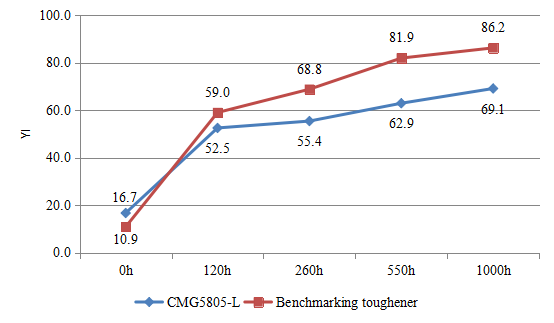

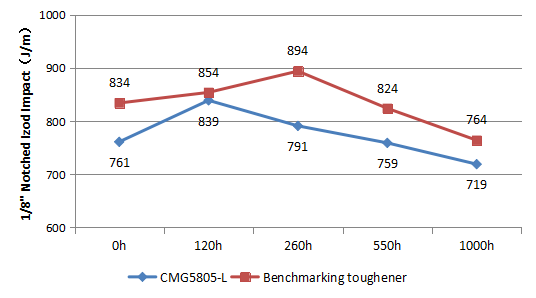

Fig.4 The yellow index variable data of toughening PA6 along with aging time

Fig.5 The ΔE variable data of toughening PA6 along with aging time

As shown in Fig.4 and 5, parallel adding CMG5805 with adding benchmarking in toughening PA6, with the increasing of the aging time, the color stability of the former is better.

Note: PA6 viscosity of 2.45 in experiment, and PA6/toughening agent = 85/15

Case 3: The influence of CMG5805-L on aging properties (aging temperature: 150℃) of toughening PA66

Fig.6 The notched impact variable data of toughening PA66 along with aging time

In toughening PA66, parallel adding CMG5805-L with adding US benchmarking, the toughness of adding benchmarking product is better, however, when the aging time after 1000 hours, their toughness retention are similar(Fig.6).

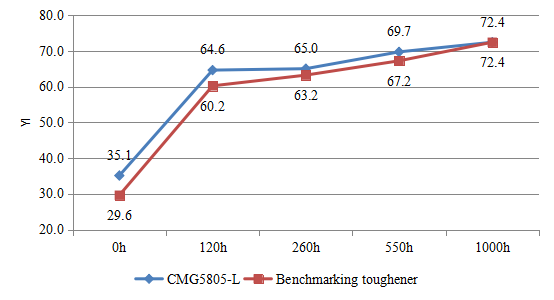

Fig.7 The yellow index variable data of toughening PA66 along with aging time

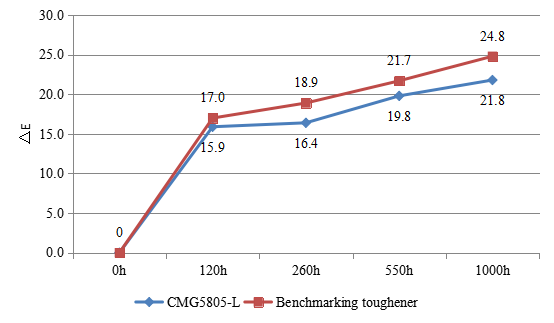

Fig.8 the ΔE variable data of toughening PA66 with thermal aging time

The YI and ΔE changing of PA66 with 15% CMG5805-L and 15% benchmarking as toughening agent are shown in Fig.7 and 8, respectively. The ΔE changing of PA66 with 15% CMG5805-L is smaller than with 15% benchmarking product as the thermal aging time increases.

Note: PA66 viscosity of 2.7 in experiment, and PA66/toughening agent = 85/15

Note: These are tipical properties only and are not to be construed as specifications.

Recommended Dosage

3-20%, can be adjusted according to the practical situation.

Processing guidelines, package & storage and safety information

Please refer to the product SDS.