FINE-BLEND® EMI-100

Masterbatch carrier activator

ABS Special masterbatch /EMI-100 High gloss ABS (frame, base)

EMI-100 masterbatch carrier activator:

1. 5% increases in the amount of carbon black, added for the preparation of a higher concentration of masterbatch.

2. Significantly improves the dispersibility of carbon black, to obtain a terminal excellent aesthetic effects products.

Tab 1. PVCModified basic formula

|

1#

|

2#

|

|

|

PVC(Degree of polymerization=1000,Extrusion grade)

|

100

|

100

|

|

Composite stabilizer

|

1.7

|

1.7

|

|

Toughening agent CPE(Chlorine content,36%)

|

6

|

6

|

|

CaCO3

|

12

|

12

|

|

HSt

|

0.3

|

0.7

|

|

Foreign brands(ACR)

|

2

|

/

|

|

EMI-100

|

/

|

2

|

Tab 2. Two types of processing aids for PVC processing performance

|

Material composition

|

Minimum torque(N.m)

|

Maximum torque(N.m)

|

Balancingtorque(N.m)

|

Plasticizing time(s)

|

|

6.9

|

37.8

|

27.6

|

70

|

|

|

PVC/EMI-100

|

6.4

|

31.9

|

21.4

|

63

|

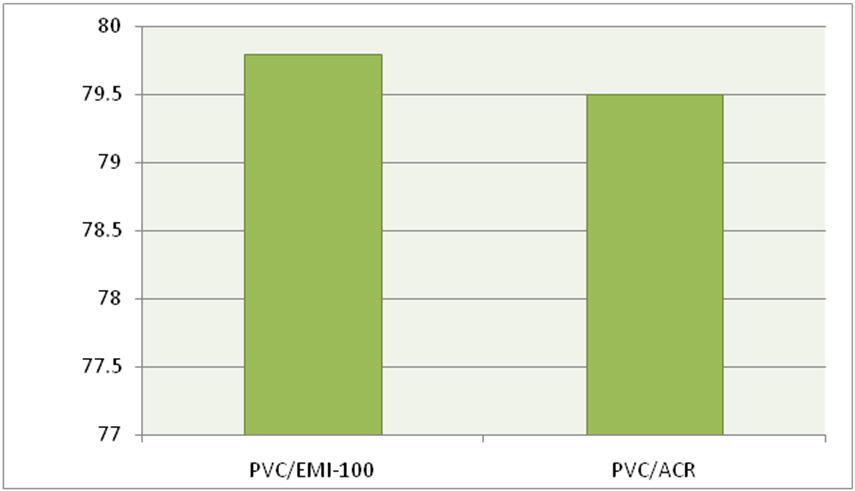

Figure1.Two types of processing aids for PVC heat resistance(Vicat)

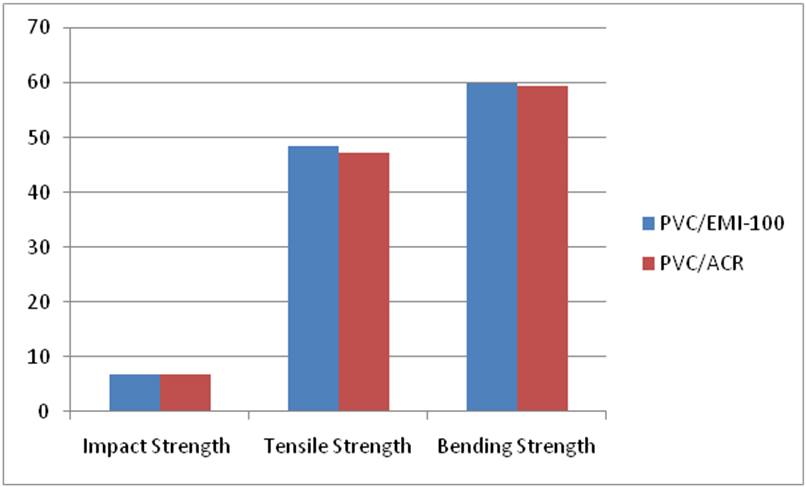

Figure 2. Two types of processing aids for PVC mechanical properties

Figure 2 shows that ,compared with foreign products,has a considerable mechanical properties.

Previous: Polymer chain extender for the R-PC, R-PET, R-PA, etc. Next: Additive for Glass Fiber reforced ABS or AS