Modifiers for Glass Fiber-reinforced Polypropylene

2019-02-17 13:16:00 Source: Views:

Case 1: Application of CMG9801 in GF reinforced PP

Tab.1 Physical and Chemical Properties of PP+30% GF system

|

PP/GF/CMG9801

|

Tensile strength

/MPa

50mm/min

|

Flexural strength

/MPa

2mm/min

|

Flexural modulus

/ MPa

2mm/min

|

Notched Izod impact strength

/ J/m

23℃

|

MFR

/ g/10min

230℃*2.16Kg

|

|

70/30/0

|

30

|

40

|

4300

|

78

|

12

|

|

68/30/2

|

80

|

94

|

5450

|

130

|

13

|

Notes: PP Shanghai Secco K7926; GF: Jushi 988A

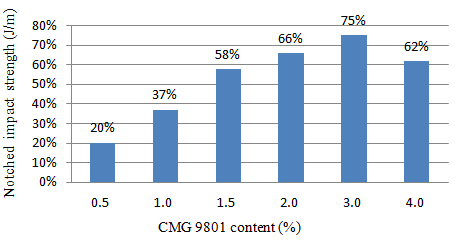

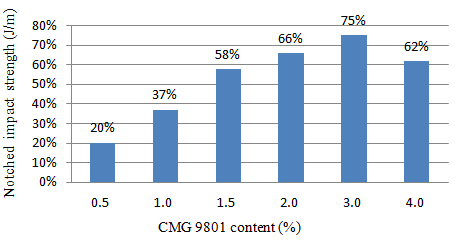

Fig.1 The effect of CMG9801 on notched impact strength of PP+30%GF system

Fig.1 shows that the notched impact strength was obviously improved with the addition of CMG9801. The impact strength reaches a maximum when the content is 3%.

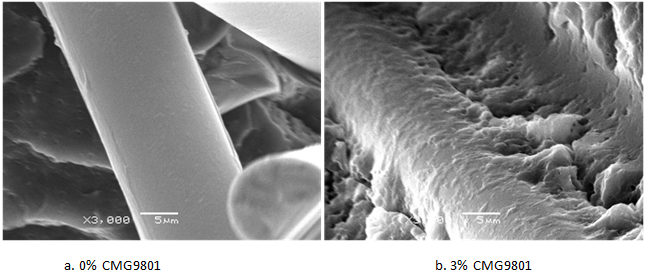

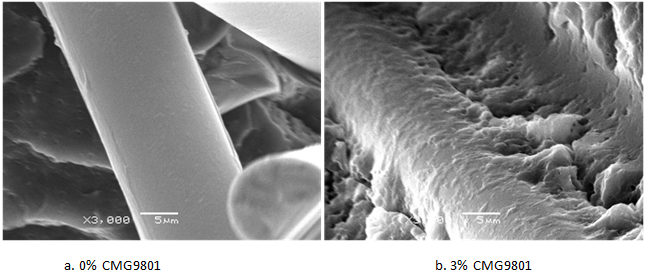

Fig.2 The SEM graph of PP+30%GF system without and with 3% CMG9801

As shown in fig.2, the compatibility between PP matrix and GF was obviously enhanced with the introduction of CMG9801, this is essential to obtain high mechanical performance, and for the final products the phenomenon of “glass emergence” can also be improved.

Case 2: The effect of CMG9801 on the long-term heat aging properties of PP+30%GF system

Fig.3 The effect of CMG9801 on the long-term heat aging properties of PP+30%GF system

As shown in fig.3, the samples added CMG9801 have a much better long-term heat aging properties than domestic products, especially when the aging time longer than 900h. And the CMG9801 still have advantages compared with the imported product.

Previous: Nylon impact modifier

Next: How to improve the properties of PA6/PP alloy?