Product Introduction

Fine-Blend® CMG9801 is a kind of general PP-g-MAH compatibilizer with excellent comprehensive properties. The introduction of active anhydride groups, the adhesion between PP matrix and fillers (GF, Talc, Wood Floor and so on) can be greatly improved, and then the mechanical properties such as tensile strength, flexural strength and impact strength could also be significantly improved.

Application Case

Case 1: Application of CMG9801 in GF reinforced PP

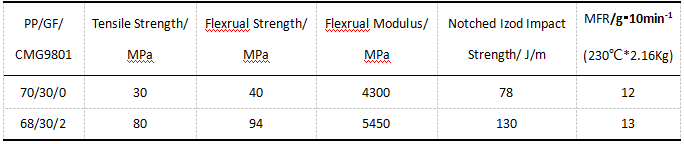

Tab.1 Physical and Chemical Properties of PP+30% GF system

Notes: PP Shanghai Secco K7926; GF: Jushi 988A

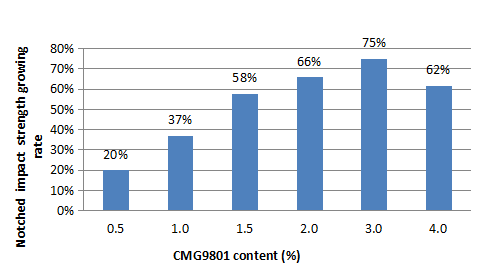

Fig.1 The effect of CMG9801 on notched impact strength of PP+30%GF system

Fig.1 shows that the notched impact strength was obviously improved with the addition of CMG9801. The impact strength reaches a maximum when the content is 3%.

a. 0% CMG9801 b. 3% CMG9801

Fig.2 The SEM graph of PP+30%GF system without and with 3% CMG9801

As shown in Fig.2, the compatibility between PP matrix and GF was obviously enhanced with the introduction of CMG9801, this is essential to obtain high mechanical performance, and for the final products, the phenomenon of “glass emergence” can also be eliminated.

Case 2: Fine-Blend® CMG9801 has excellent thermal stability

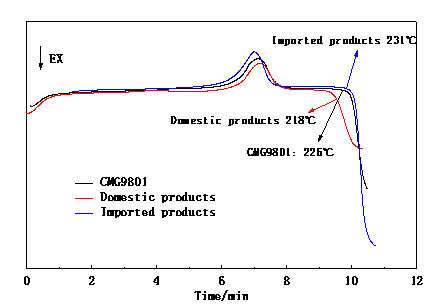

Fig.3 The oxidative induced temperature of PP-g-MAH from different maker

The thermal stability of Fine-Blend® CMG9801 under the condition of temperature and oxygen were shown in Fig.3. The oxidative induced temperature of CMG9801 is similar with imported compatibilizer, far better than domestic products. As we know that the low molecule residual,temperature and oxygen could cause the degradation of PP chains,and also the stability of compatibilizer have a great effect on the final PP/GF composites. The influence of different products on the final products was shown in Fig.4 and Fig.5.

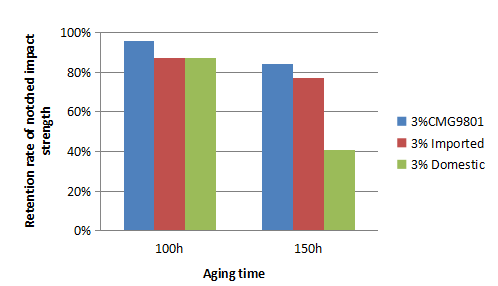

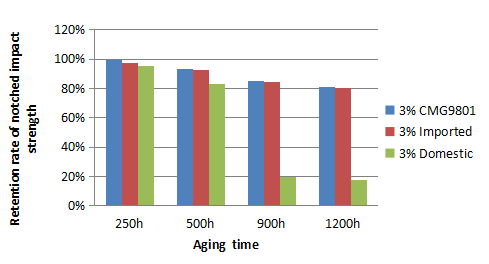

Fig.4 The influence of compatibilizer on the retention rate of impact strength of PP/30%GF system (without antioxidant)

Fig.5 The influence of compatibilizer on the retention rate of impact strength of PP/30%GF system (with antioxidant)

It is clearly shown in Fig.4 and Fig.5 that no matter with or without antioxidant after 150℃ thermal degration, the retention rate of notched impact strength of using CMG9801 system is better than using domestic products. And this phenomenon also confirmed by Fig.6.

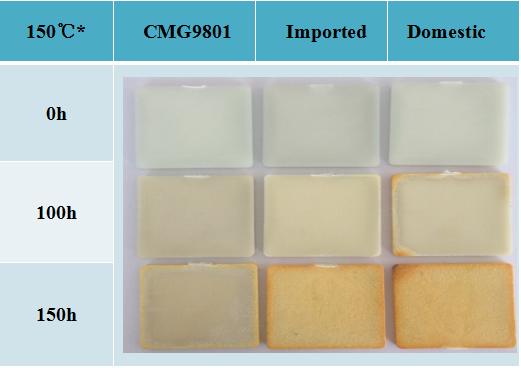

Fig.6 The influence of compatibilizer on the color changing of PP/30%GF system ( without antioxidant)

Fig.6 shows that CMG9801 not only have high impact retention rage, but also with the smallest color changing after thermal degration. So CMG9801 could meet the fields with higher color and appearance requirements.

Notes: These are typical properties only and are not to be construed as specifications.

Recommended Dosage

2-5%, can be adjusted according to the practical situation.

Processing guidelines, package & storage and safety information

Please refer to the product SDS.