Product Introduction

Fine-Blend® EMI-230B is particularly suitable for extruded sheet, blow molding, blistering ABS, ASA, PC / ABS products. It can help the material becomes even thinner, less defective product in the blow molding, extrusion molding process.

Mechanism and Advantage

Fine-Blend® EMI-230B is a long chain branched styrene-acrylonitrile random copolymer having a colorless bead-like particle appearance. EMI-230B has a special branching structure, which can change the rheological properties of the material during processing, so that the material has the ability to strain hardening, in the blow molding, extrusion molding process can be even thin, less defective product.

ABS resin in the extrusion, blow molding and other processes, if the melt strength of the material is insufficient, it is easy to produce embryo body vertical collapse, collapse and other phenomena; vacuum snap-back thermoforming ABS when the local part is too thin, a series of problems occur such as rupture. As follows:

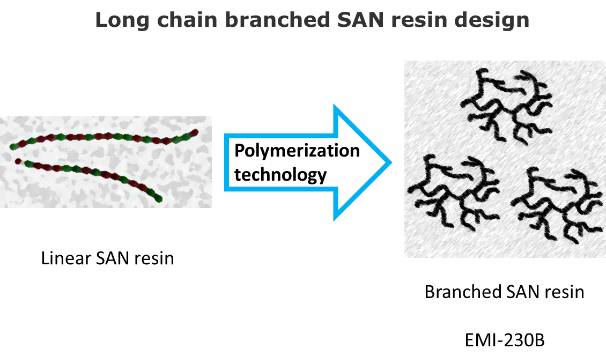

Fig.1 Schematic diagram of long chain structure EMI-230B

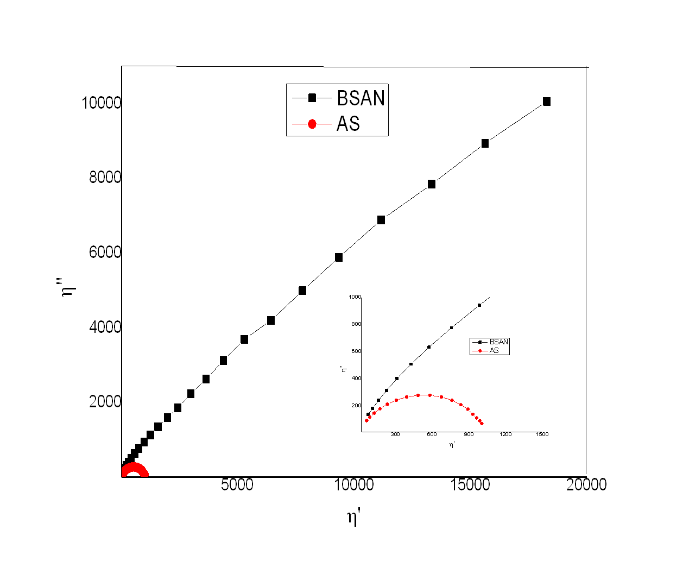

Fig.2 Rheological characterization of EMI-230B and Linear SAN (cole-cole map)

Fig.2 shows that normal SAN resin has a linear molecular structure, however, EMI-230B was designed to be a branched structure. From Fig.2, rheological test result conforms that EMI-230B is a branched molecular structure. Branched structure can bring ABS hot melt strength becomes stronger.

Application Case

Case1. Application of EMI-230B in the ABS

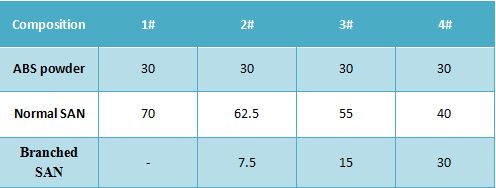

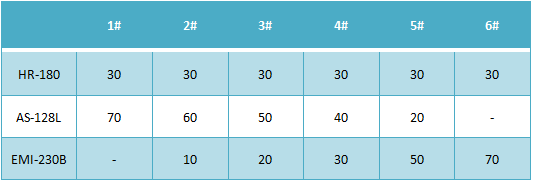

Table.1 Evaluation formula

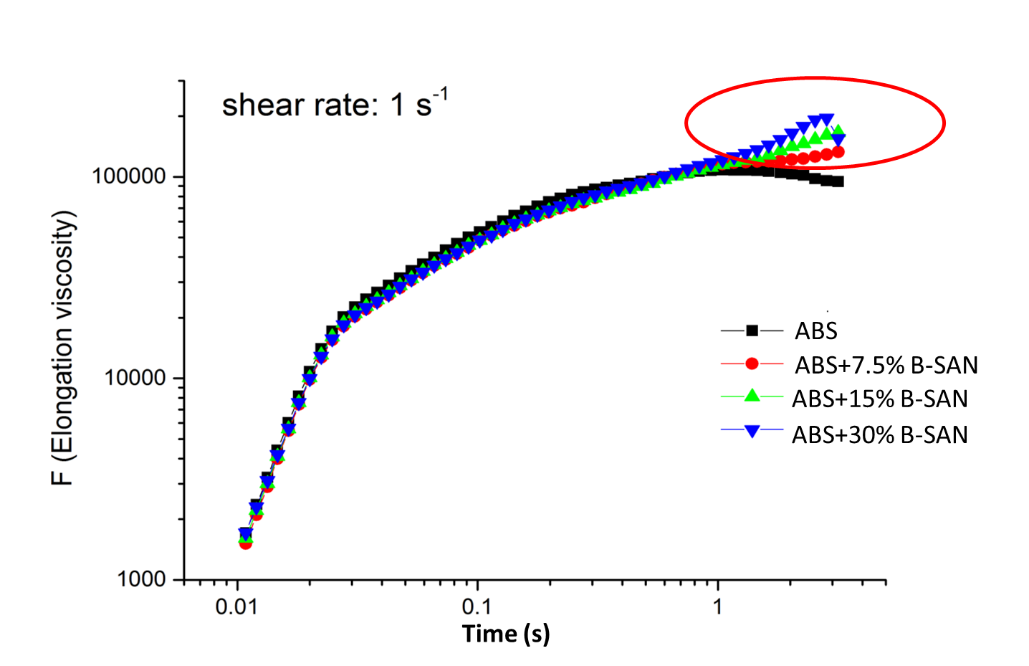

Fig.3 Extensional rheology characterization of EMI-230B in ABS

Fig.3 shows that the extensional viscosity with branched SAN turns higher than the normal ABS at the last. With the increase of EMI-230B content, the elongation viscosity also increase. The increase of elongation viscosity is very helpful for blow molding and sheet ABS process.

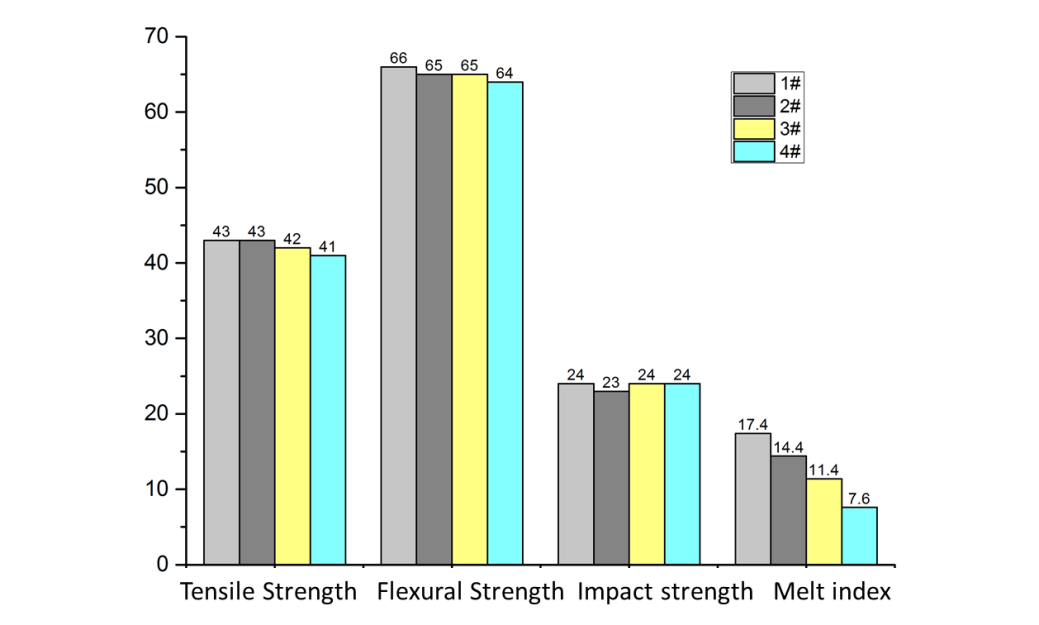

Fig.4 Physical and mechanical properties

Fig.4 shows that after adding EMI-230B, the mechanical properties are not affected. With 7.5% EMI-230B, melt index will decrease by 17.2%; with 15% EMI-230B, melt index will decrease by 34.5%; with 30% EMI-230B, melt index will decrease by 56.3%. As we all known that, the melt index will declined sharply and affect processing ability after adding super-high molecule SAN resin.

So, from Fig.3 and Fig.4, it can be concluded that EMI-230B can increase the elongation viscosity, but doesn’t have negative effect on mechanical properties and its melt index was still in good processing condition.

Table.2 Evaluation formula

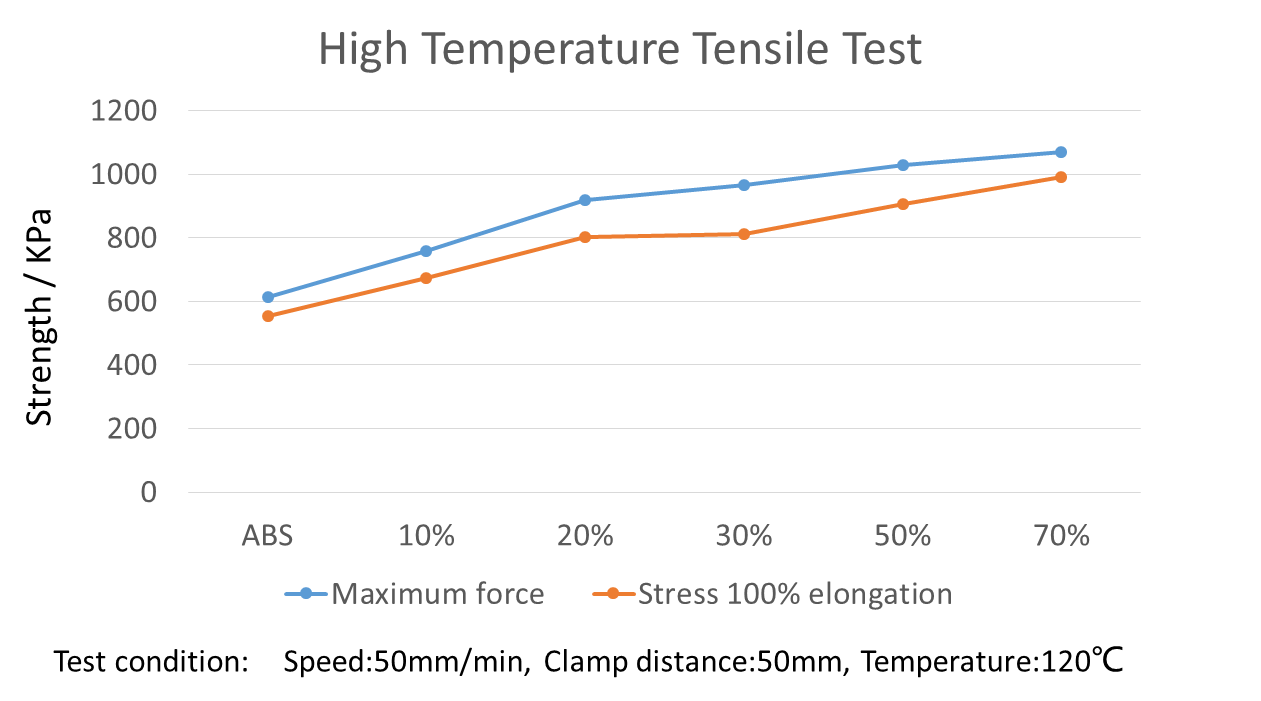

Fig.5 High temperature tensile strength

Fig.5 shows that with the increase of EMI-230B content, the maximum force and Stress at 100% elongation get higher. The high temperature tensile strength is very important factor of blow molding and sheet ABS process. Obviously, if the high temperature tensile strength is higher, and the products can be made thinner and less defective.

Recommended dosage

5-50%

Processing Guide, packaging and storing security information

Please refer to product SDS