Nylon impact modifier

2019-02-17 12:59:00 Source: Views:

Case 1: CMG9805 used in toughening nylon and reinforced and toughening nylon

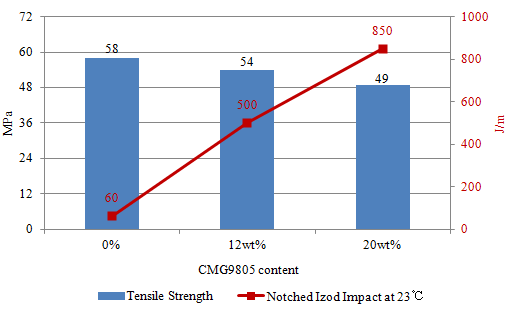

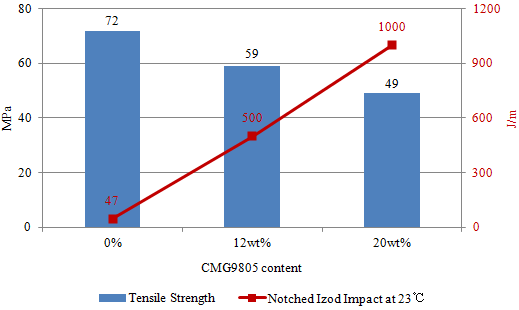

Fig.1 The effect of CMG9805 on tensile strength and notched impact of toughening PA6

In toughening PA6, adding 12% of CMG9805 or more can achieve super toughness level. (PA6 viscosity of 2.45 in experiment)

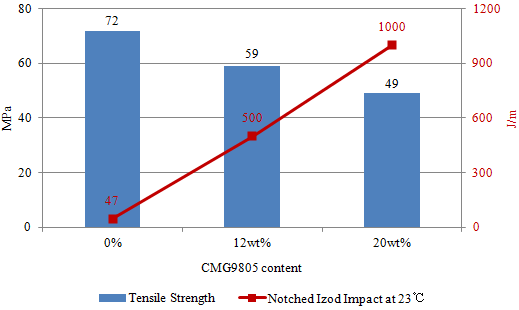

Fig.2 The effect of CMG9805 on tensile strength and notched impact of toughening PA66

In toughening PA66, adding 12% CMG9805 or more can achieve super toughness level. (PA66 viscosity of 2.7 in experiment)

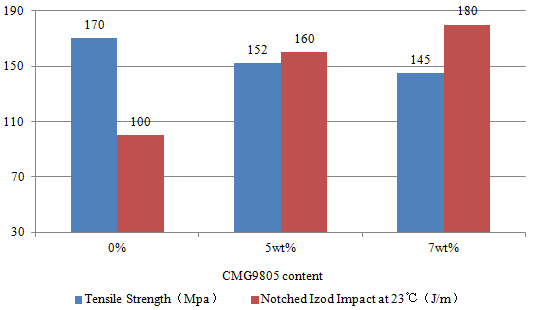

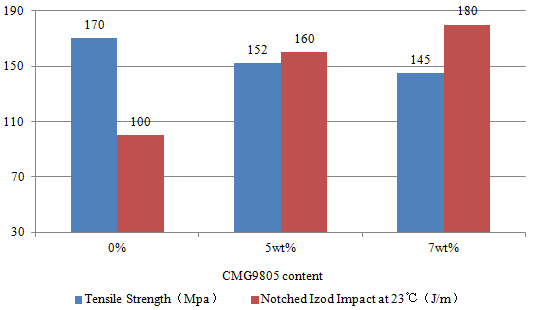

Fig.3 The effect of CMG9805 on tensile strength and notched impact at 23 ℃ of reinforced and toughening PA6 (30% glass fiber)

In reinforced and toughening PA6 (30% glass fiber), adding 5% and 7% of CMG9805, the growth can reach more than 40% and 85% of notched impact strength at 23℃ respectively. With the increasing of toughening agent, the tensile strength will be reduced. (The glass fiber is JuShi 988A and the viscosity of PA6 is 2.45 in experiment)

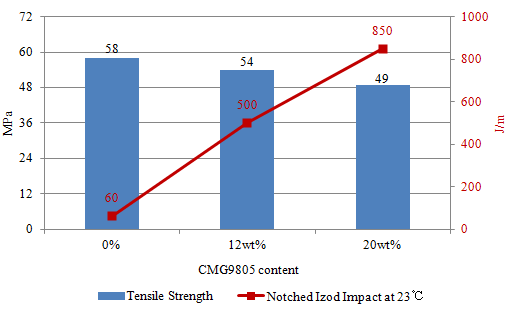

Fig.4 The effect of CMG9805 on tensile strength and notched impact at 23 ℃ of reinforced and toughening PA66 (30% glass fiber)

In reinforced and toughening PA66 (30% glass fiber), adding 5% and 7% of CMG9805, the growth can reach more than 60% and 80% of notched impact strength at 23℃ respectively. With the increasing of toughening agent, the tensile strength will be reduced. (The glass fiber is JuShi 988A and the viscosity of PA66 is 2.7 in experiment)

Previous: Toughening Agent for PBT

Next: Modifiers for Glass Fiber-reinforced Polypropylene